Spring Cleaning for Commercial Kitchens: Essential Equipment Maintenance Tips

Feb 7th 2026

Reading Time: 4 Minutes

Winter takes a toll on commercial equipment. Heating systems run overtime, grease congeals faster in colder drains, and condensers collect layers of stagnant dust. As the weather warms up, the load shifts heavily to refrigeration and ice machines.

If kitchens don't prep their equipment now, they'll be facing walk-in disasters during a heatwave.

For a service company, this is the perfect opportunity to upsell a "Spring PM Special." Use this checklist to guide your technicians and show value to your customers.

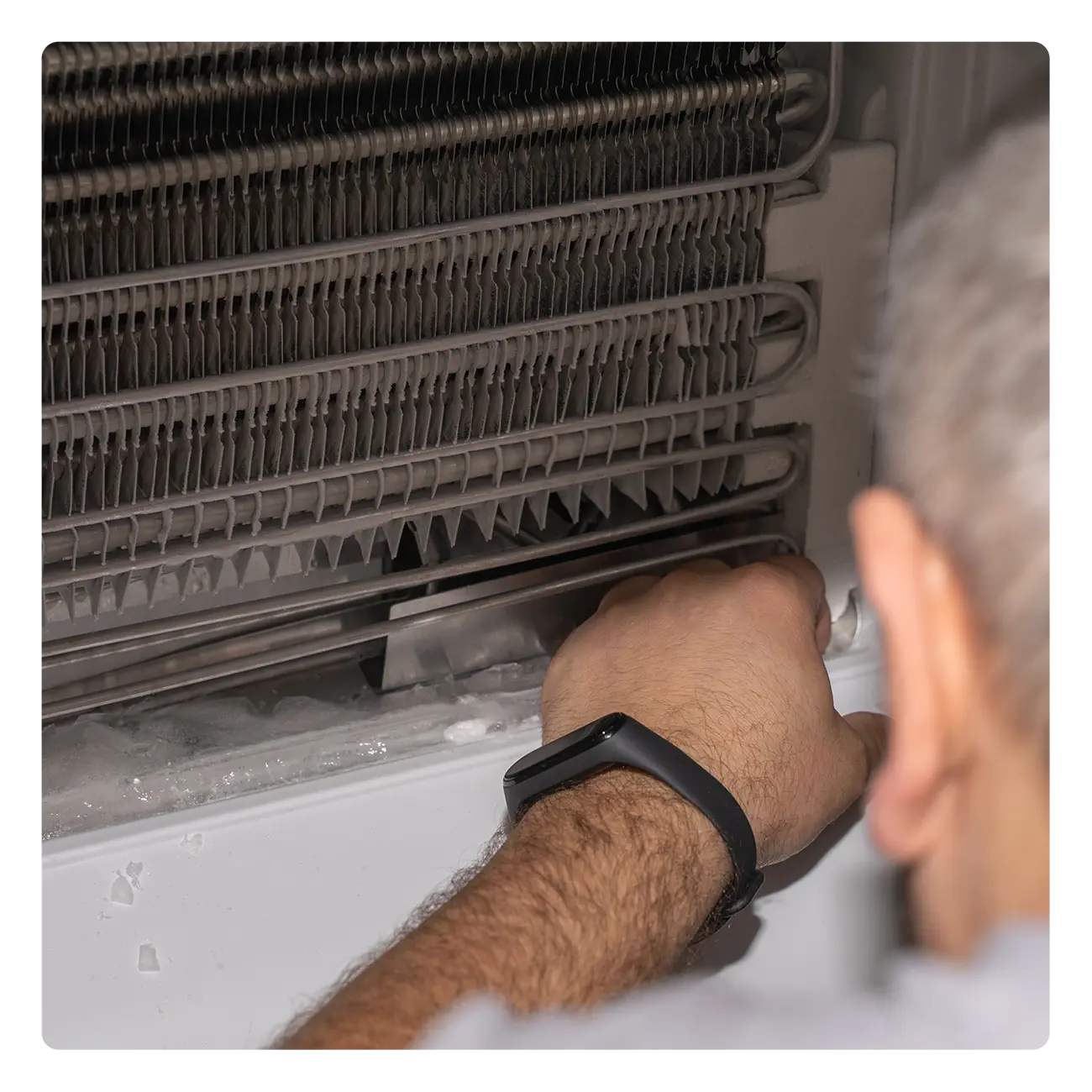

1. Refrigeration

The #1 killer of compressors is a dirty condenser coil. After a long winter, these are likely clogged with dust and cardboard fibers.

- Clean Condenser Coils: Use a brush and vacuum cleaner to suck out the debris. A blocked coil drives up energy bills and head pressure.

- Check Door Gaskets: Cold air leaking out forces the compressor to run 24/7. Inspect walk-in and reach-in gaskets for tears or brittleness.

- Clear Drain Lines: Algae and slime love the transition to warmer weather. Blow out evaporator drain lines to prevent water backups.

2. Ice Machines

Ice safety is a major health department focus.

- Descale and Sanitize: Run a full cleaning cycle with nickel-safe cleaner to remove lime scale and mold.

- Change Water Filters: Winter sediment can clog filters. Write the date on the new cartridge.

- Check the Air Filter: Air-cooled machines need to breathe. If the filter is matted with grease/dust, the ice production will drop by half.

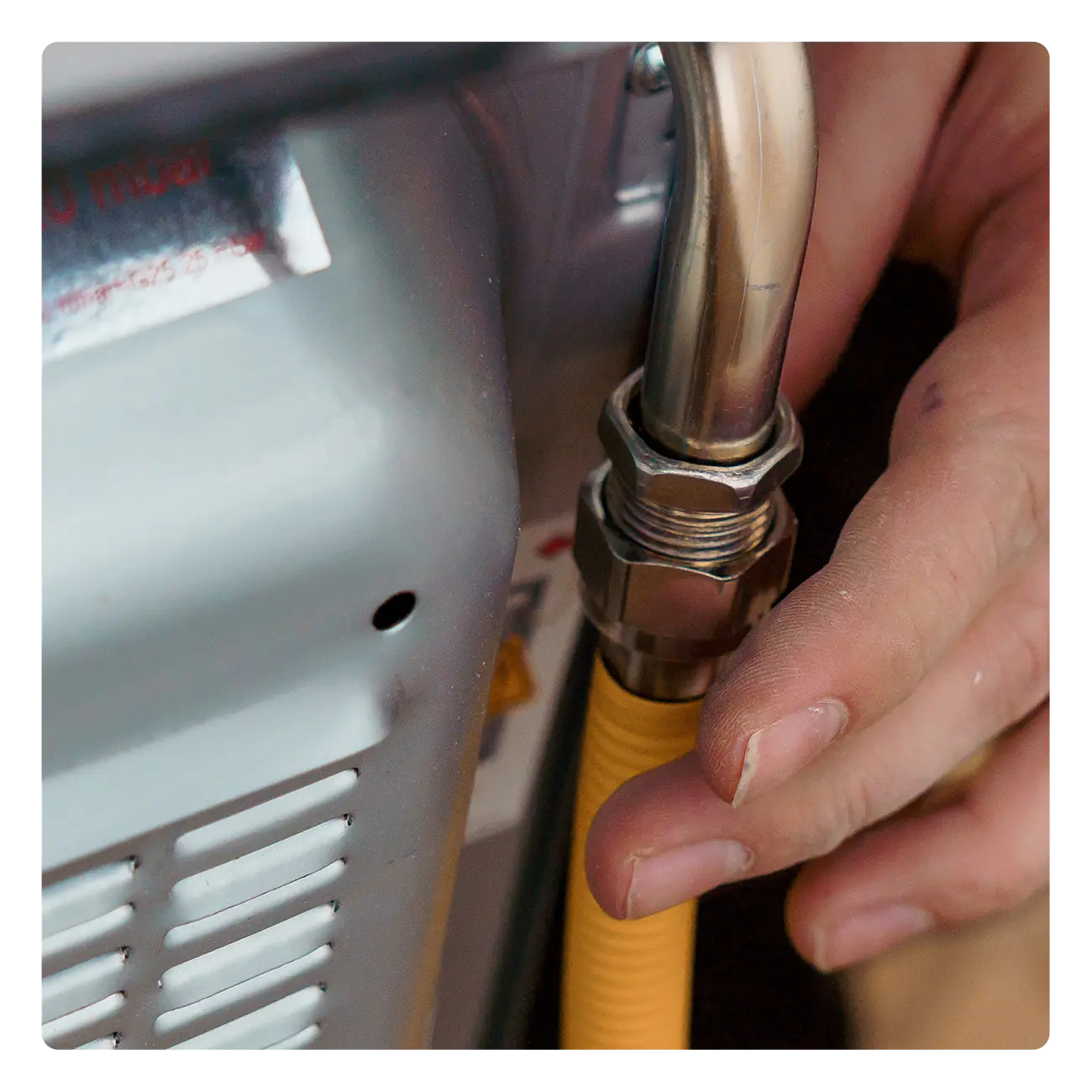

3. Cooking Equipment

- Fryer Boil-Out: Carbon buildup on the heating tubes acts as insulation, slowing down recovery time. Recommend a professional boil-out.

- Calibrate Ovens: Thermostats drift over time. Verify temperature accuracy before the busy season.

- Inspect Gas Hoses: Look for cracks or wear on the quick-disconnect hoses behind the line.

4.Commercial steamer

- Descaling (Deliming): Use manufacturer-approved descaling chemicals to remove lime buildup inside the steam generator, which is crucial for efficiency.

- Probe Cleaning: Clean water level sensors/probes with a soft brush to ensure accurate readings.

- Exterior Inspection: Check for any signs of steam leaks, which indicate faulty gaskets.

Periodic Maintenance

- Water Filtration: Replace water filters and cartridges every 3–6 months to prevent scale from entering the system.

5. HVAC & Ventilation

- Replace MUA Filters: Makeup Air units suck in pollen and leaves during the spring. Clogged filters throw off the kitchen's air balance.

- Check Belts: Winter starts can be hard on belts. Check for cracking or glazing on exhaust fan belts.

6. The "Truck Stock" Opportunity

While you are performing these checks, have your techs look for "consumables" that are about to fail.

- Knobs & Dials: Are they cracked or spinning loose?

- Cutting Boards: Are they deeply scored?

- Lights: Are the bulbs in the walk-in or oven blown out?

Turn Maintenance into Revenue

Don't wait for the phone to ring with an emergency. Be proactive. Send this checklist to your customers and offer to perform the service. You’ll save them from a mid-summer breakdown and fill your schedule with profitable planned maintenance.

Need supplies for the job?

From condenser brushes and coil cleaner to OCM door gaskets and water filters, find everything you need for Spring PMs at AllPointsFPS.com.