How to Manage Cash Flow When You're Paying for Parts (Before You Get Paid)

Jan 20th 2026

Reading Time: 4 Minutes

The toughest part of the foodservice repair business isn't the technical work. It's the math.

Specifically, it’s the "float." You ordered a $400 blower motor today, so you pay your supplier (or put it on credit) and install it tomorrow. Then, you invoice the restaurant. But then...you wait. In this industry, net-30 often stretches to net-45 or net-60.

Essentially, you are acting as a bank for your customers. You are financing their repair while your cash is tied up in the part. If you do this enough times in a month, you can be profitable on paper but broke in the bank account.

Here are four practical strategies to tighten that gap and keep your cash flow healthy.

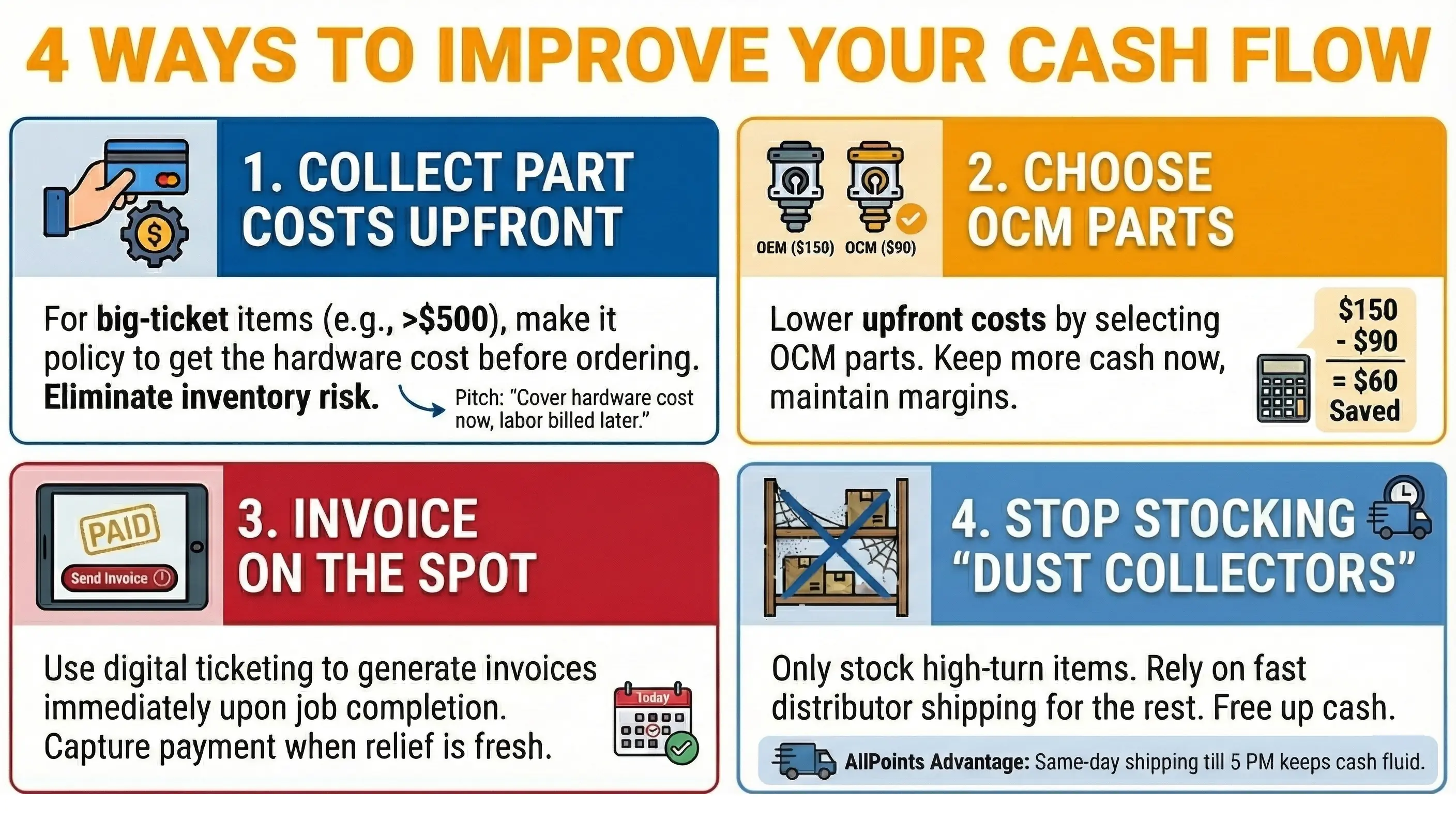

1. The "50% Rule" for Big Ticket Items

Never be afraid to ask for a deposit on expensive parts. If a repair requires a part over a certain threshold (e.g., $500 or $1,000), make it company policy to collect the cost of the part upfront before you place the order.

- The Pitch: "To get this compressor ordered and shipped today, we just need to cover the hardware cost. The labor will be billed upon completion."

- The Result: You eliminate the risk of holding the bag on expensive inventory if the customer changes their mind or goes out of business.

2. Lower Your "Upfront" Cost with OCM parts

One of the fastest ways to improve cash flow is simply to send less cash out the door.

- The Scenario: You need an ignition module. The OEM version costs you $150. The OCM version costs you $90.

- The Math: By choosing OCM parts, you keep $60 in your operating account right now. You can still charge the customer the standard market price for the part, which actually increases your margin and preserves your cash reserves simultaneously.

3. Invoice on the Spot (Digital Ticketing)

If you are still mailing invoices or typing them up on Friday nights, you are voluntarily delaying your own payday.

- The Fix: Technicians should have the ability to generate the invoice on their tablet or phone the moment the job is marked "Complete."

- The Benefit: Many restaurant managers can cut a check or swipe a credit card immediately if the invoice is presented while the relief of the "fixed equipment" is fresh. The longer you wait to send the bill, the less urgent it feels to them.

4. Stop Stocking "Dust Collectors"

Truck stock is necessary, but "just in case" inventory is a cash killer. Every part sitting on a shelf for more than 6 months is a pile of cash that you can't use for payroll or fuel.

- The Fix: Review your purchasing history. Only stock high-turn items (thermocouples, fuses, common sensors). For everything else, rely on a distributor with fast shipping.

- AllPoints Advantage: Because we offer same-day shipping until 5 PM, you don't need to hoard parts. You can order exactly what you need, exactly when you need it, and keep your cashflow fluid.

Summary

You aren't a bank — you're a service provider. By collecting deposits on big jobs, buying smarter with OCM parts, and invoicing instantly, you can stop stressing about the float and focus on growing the business.

Want to lower your parts spend without sacrificing quality?

Check out the price difference on OCM parts for your next job at AllPointsFPS.com.